Detailed Analysis of Heat Load Reduction on Divertor Plates Using Experiments and Simulations

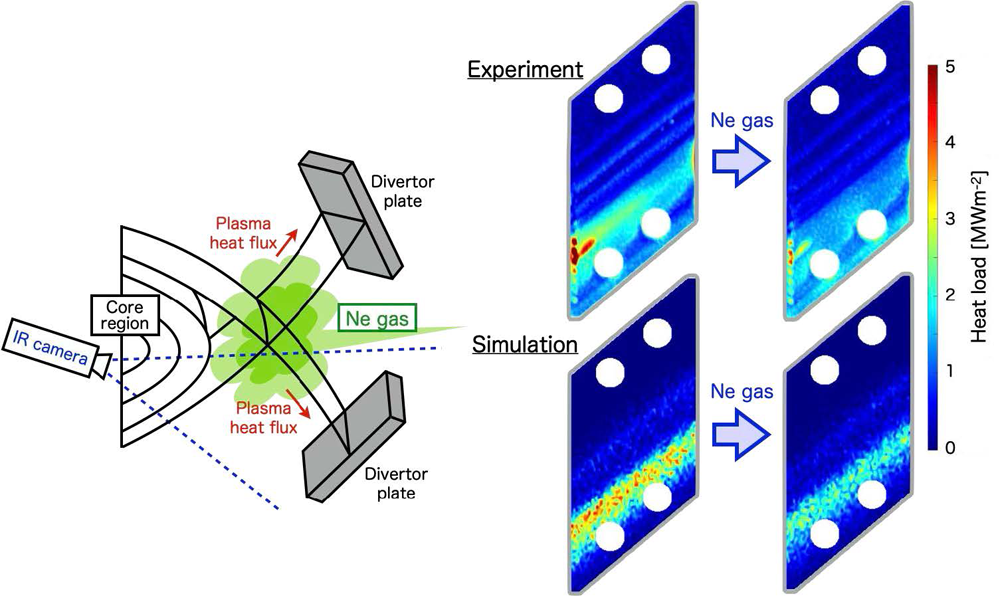

This study demonstrates how heat load control can be achieved in nuclear fusion reactors. By injecting impurities such as neon, plasma energy can be effectively dissipated, preventing excessive heat concentration in specific areas. Using a combination of experiments and simulations, we have clarified that the effectiveness of heat load mitigation depends strongly on the magnetic field structure. Findings of this study provide crucial insights for optimizing heat load control in future fusion reactors.

In fusion reactors, extremely high-temperature plasma generates large amounts of energy, part of which flows into the divertor plate. If the heat load on the divertor plate becomes too high, it can lead to material damage, making stable operation difficult. In this study, we investigated a method to reduce the heat load by using radiative cooling through the injection of impurities such as neon (Ne) in the Large Helical Device (LHD). We focused on how the heat load mitigation technique affects multiple heat load peaks on the divertor plate.

Our research team injected small amounts of Ne gas into plasma in LHD and observed the changes in divertor heat load. The surface temperature of the divertor was measured using an infrared camera, and the heat load distribution was analyzed using the finite element method. Additionally, we performed numerical simulations using the EMC3-EIRENE code and compared the calculated heat load with experimental results, to gain deeper insights into the heat load reduction mechanisms.

Experimental results confirmed that Ne injection significantly reduced the heat load on the divertor. However, the effect varied depending on the location of the heat load peaks. Under lower heating power, the widely distributed heat load peaks were mitigated, whereas at higher heating power, the same region showed little change. However, another localized heat load peak was significantly reduced. Comparisons with simulations revealed that these variations were related to the magnetic field structure. The shape of the magnetic field determines where plasma heat is concentrated, while different heating power influences the depth to which Ne can penetrate the plasma. These findings suggest that, in future fusion reactors, efficient heat load mitigation should take into account both the magnetic field structure and impurity penetration to prevent divertor damage and ensure stable operation.

This study provides new insights into impurity injection as a method for reducing divertor heat loads in fusion reactors. Both experimental and simulation results confirmed that Ne injection effectively mitigates heat load peaks. Previous studies have rarely performed such detailed comparisons between experimentally measured and simulated 2D divertor heat load distributions. Furthermore, we have demonstrated that the effectiveness of heat load reduction is influenced by the magnetic field structure and the ability of impurities to penetrate the plasma. These findings are expected to contribute to the design and operation of future fusion reactors.

This research was carried out by a group led by Dr. Yuki Hayashi at the University of Tokyo, Dr. Gakushi Kawamura at the National Institutes for Quantum Science and Technology, and Prof. Suguru Masuzaki and Dr. Masahiro Kobayashi at the National Institute for Fusion Science.

These results were published in Plasma Physics and Controlled Fusion, an international journal of plasma physics, on January 6, 2025.