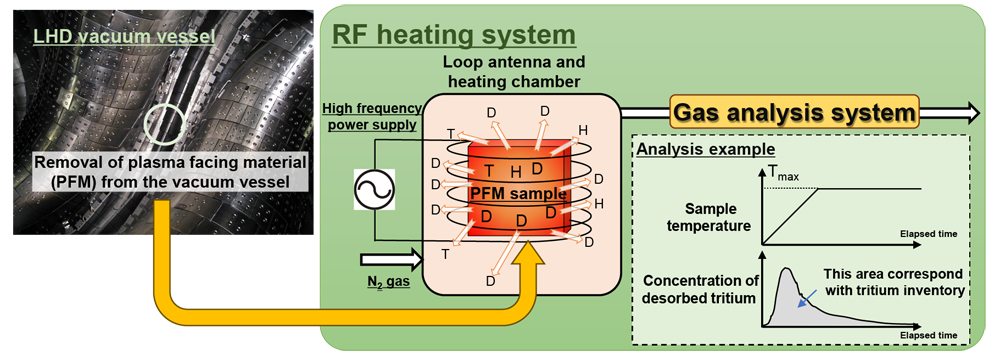

Development of new analytical method to investigate tritium inventory in plasma-facing materials

Plasma-facing material in the Large Helical Device (LHD) contains a small amount of tritium produced in deuterium experiments. To analyze it we have developed a new system using an induction heating method. With this technique, a tritium inventory, release behavior, and the chemical form of released tritium were clarified. By elucidating the tritium inventory and distribution in fusion devices, the new system will contribute to research on tritium safety and fuel balance in fusion reactors.

Future fusion reactors will use deuterium and tritium as fuels, and the energy generated by their reaction will be converted into heat and electricity. However, the reaction rate is low, and most of the fuel is exhausted from the fusion device without reacting, while the rest remains in the plasma-facing material. It is required from the viewpoint of fusion safety and reactor system design to clarify where and to what extent hydrogen isotopes are retained in the fusion device.

We have been engaged in the analysis of tritium in plasma-facing material: carbon tiles installed in the vacuum vessel, using a very small amount of tritium produced in the deuterium experiment in LHD as a tracer. The imaging plate method, which visualizes tritium near the surface, and the thermal desorption and combustion methods, in which a portion of a carbon plate is cut out and heated for analysis, have been developed as methods for analyzing tritium in carbon tiles. These methods are known to be useful for tritium analysis in materials; however, they have some limitations such as being restricted to analyzing only the surface or a small portion of a carbon tile. Therefore, we developed a high-frequency heating analysis system using an induction heating method that can heat large carbon tiles in which tritium is retained in an “as is” form. Induction heating is a familiar heating method that is also used in home cooking stoves such as IH cooking heaters.

In induction heating, a time-varying magnetic field is created by passing an alternating current through a loop antenna (coil). When a metal sample is placed near this antenna, an electric current (eddy current) flows through the metal, directly heating the sample, due to the electrical resistance of the metal. The induction heating method has the following features: rapid and high-temperature heating of a large sample is possible by optimizing the coil shape and AC frequency, its heating control is ready and has a quick-response; it is safe because it has little thermal effect on the surroundings, and it saves power and space.

When carbon tiles containing tritium were heated to over 1100 C using the developed high-frequency heating analysis system, it was found that helium was released from the carbon tiles at relatively low temperatures in the initial stage of heating, while hydrogen and tritium were released at higher temperatures. Furthermore, a detailed analysis of the chemical form of tritium revealed that approximately 80 % of the tritium released was in the chemical form of molecular hydrogen, while the remainder was in the form of water vapor. Although the carbon tiles removed from the vacuum vessel were placed in the atmosphere at room temperature, it was found that not only tritium but also helium and hydrogen components used in plasma experiments remained for a long period of time. In addition, by cutting the carbon tiles into small pieces before and after heating and analyzing the depth distribution of tritium by cutting samples at 1 mm intervals from the surface, it was confirmed that the tritium, which was mostly retained near the surface before heating, was greatly reduced by being released from the surface by heating. After heating for 18 hours at a temperature of 1100 C or higher, the tritium inventory in the carbon tiles was reduced to less than 0.4 % of that before heating (more than 99.6 % of the retained amount was released). This result indicates that the induction heating method is effective not only for obtaining tritium inventory data in carbon tiles but also for safety measures such as “decontamination and removal” of tritium from carbon tiles.

In our previous work on the behavior of tritium produced in deuterium experiments in LHD (“Explore the behavior of hydrogen isotopes using a tracer”), we reported on exhaust behavior during plasma experiments, its chemical form, and mass balance. The tritium inventory in the LHD can be estimated by analyzing the plasma-facing material installed in the vacuum vessel using the newly developed heating analysis system. Comparing the results of this analysis with the tritium inventories estimated in previous studies will lead to a comprehensive clarification of tritium behavior. However, there are a large number of plasma-facing materials in LHD to be analyzed, and now that we have developed the radio frequency heating analysis system, we are just at the beginning of our research. We will continue to analyze the tritium inventory in plasma-facing materials to clarify the tritium balance in the LHD system.

This research result was published in Nuclear Materials and Energy, a journal on material application in the production of nuclear energy, on January 21, 2025.