Demonstration That Amount of Absorbed Heat Depends on Material Properties Despite Identical Plasma Exposure

This study has experimentally demonstrated that heat absorption from plasma depends on the wall material. In the Large Helical Device (LHD), tungsten and carbon were exposed side by side to identical plasma. Tungsten, known for its high energy reflection, absorbed less heat than carbon. This result provides valuable insight into designing future fusion reactors, particularly in material selection and heat management.

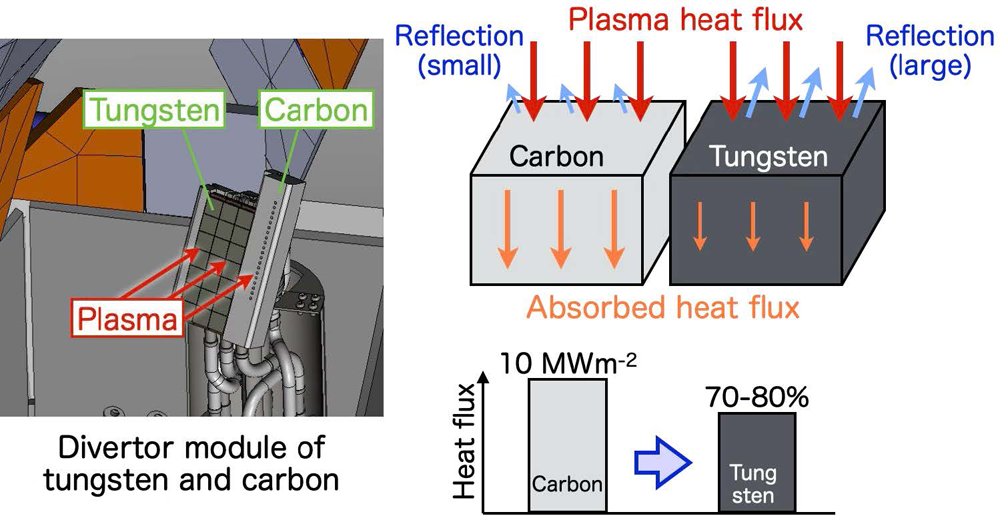

In fusion reactors, the divertor plays a crucial role in exhausting the heat from high-temperature plasma. Traditionally, carbon fiber composite (CFC) materials have been used for divertor components. However, for next-generation reactors, tungsten is considered a promising candidate due to its high melting point and low fuel retention. One of the key properties of tungsten is its high energy reflection coefficient, meaning it reflects ions and atoms with relatively high energy. This characteristic can influence the distribution of neutral gas and exhaust performance near the divertor. Differences in energy reflection coefficients among materials also result in differences in the amount of absorbed heat flux. There have been no direct observations of heat absorption differences between carbon and tungsten under actual divertor plasma conditions. The aim of this study is to provide such experimental verification.

A specially designed divertor module equipped with both carbon and actively cooled tungsten plates was installed in LHD. These materials were simultaneously exposed to the LHD plasma. Surface temperatures were measured using infrared thermography, while internal temperatures were recorded using thermocouples. The emissivity of the tungsten surface was independently calibrated and used to correct the infrared measurements. The observed temperature distributions were converted into heat-flux values using finite element analysis. Additionally, the energy reflection coefficient was estimated based on empirical formulas, and the resulting heat flux was calculated using sheath theory for comparison with experimental values.

In hydrogen discharges, measurements from the infrared camera and thermocouples revealed that the heat flux to the carbon surface reached approximately 10 MW/m2, whereas that to the tungsten surface was about 75 % of that value. This difference indicated that the tungsten reflected hydrogen ions with higher energy than did carbon, resulting in less heat being deposited into the material. The ratio of heat flux absorbed by tungsten and carbon was also consistent with that predicted by sheath theory, providing quantitative evidence that differences in energy reflection properties are the primary cause of the observed heat-flux discrepancy. Furthermore, this study demonstrated that combining thermocouple data and finite-element analysis is effective in compensating for measurement uncertainties in infrared diagnostics, particularly for low-emissivity materials like tungsten.

This research represents the first direct observation of heat absorption differences between tungsten and carbon under identical divertor plasma conditions. It clearly shows the impact of material-dependent energy reflection coefficients on the actual heat load. Effective heat management is a critical consideration in the design of fusion reactors, and these findings offer important guidance for divertor cooling design and material selection. Additionally, the results highlight the need for improved accuracy in infrared diagnostics for low-emissivity materials such as tungsten, contributing to the advancement of diagnostic techniques for future fusion devices.

This research was carried out by a group led by Dr. Yuki Hayashi at the University of Tokyo, Dr. Yukinori Hamaji and Prof. Masayuki Tokitani at the National Institute for Fusion Science.

The research results were published on 6 November 2025 in Fusion Engineering and Design, an international journal on fusion energy and technology.