A new self-consistent analytical method to calculate the behavior of boron dust particles in plasma!

A new self-consistent analytical method has been developed for calculating the trajectory of solid boron dust particles in plasma. Boron dust particles produce boron ions which flow out of the plasma through diverter legs. Although it was expected that the trajectory of the dust particles would be deflected to the outboard side of the torus by the boron ion flow effect, a detailed analysis using the method revealed that the trajectory was deflected to the inboard side.

In the Large Helical Device (LHD), experiments to drop small solid boron particles (dust) into plasma have been conducted. The dust particles entering into the plasma melt and evaporate from the plasma heat load. Since this phenomenon produces an impurity source, it is a very important topic to accurately predict the evaporation position of the dust particles in advance.

The prediction of the evaporation position requires a self-consistent analysis of the trajectory of the dust particles. Impurity atoms evaporated from the dust particles ionize in the plasma. Impurity ions flow out of the plasma through divertor legs. The impurity ion flow in the divertor leg deflects the trajectory of the dropped dust particles, changing the evaporation position of the impurity atoms. That is, the impurities released from the dust particles themselves determine their ionization positions. For this reason, a new analysis method has been developed, which can self-consistently calculate the three-dimensional trajectories of the dust particles. In the following, the analysis is explained in order.

① Using an edge plasma simulation code (EMC3-EIRENE), the three-dimensional profile of plasma parameters (the ion and electron temperature and the density, etc.) under a specified experimental condition is calculated. ② Using a dust transport simulation code (DUSTT), the three-dimensional trajectory of dropped dust particles and the production rate of the impurity atoms are calculated. ③ Using the profile of the impurity atoms, the density and flow profiles of the impurity ions in the plasma are calculated using EMC3-EIRENE. ④ The impurity radiation profile in the plasma is calculated, by which the three-dimensional profile of the plasma parameters is calculated again. ⑤ Considering the new calculation of the plasma parameter profiles and the effect of the impurity ion flow obtained in step ③, the trajectory of the dust particles and the production rate of the impurity atoms are calculated again. After this, by repeating steps ④ and ⑤, a converged solution is obtained, which is consistent with both the trajectory of the dust particles and the plasma parameter profile.

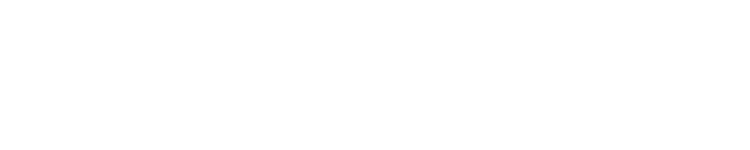

This calculation method was applied to the analysis in the case of dropping boron dust particles into LHD plasmas, which provided simulation results that were different from what was expected. Figure 1 shows a three-dimensional model (for a toroidal angle of 18 degrees) of the LHD vacuum vessel used in the analysis. In this simulation, boron dust particles were dropped from just above an upper diverter leg (the yellow circle in the figure). Here, we focused on the dependence of the change of the trajectory on the dust drop rate (number of dropped impurity atoms per second). The dropped boron dust particles produce boron ions in the plasma. The boron ions flow out of the plasma through the diverter leg. The dropped dust particles cross the upper divertor leg before reaching the peripheral plasma. The direction of the plasma (hydrogen ion) flow in the divertor leg is the outboard side of the torus. Thus, the direction of the boron ion flow is also the outboard side. The effect of the boron-ion flow deflects the trajectory of the dropped dust particles toward the outboard side, which is expected to increase with the dust drop rate.

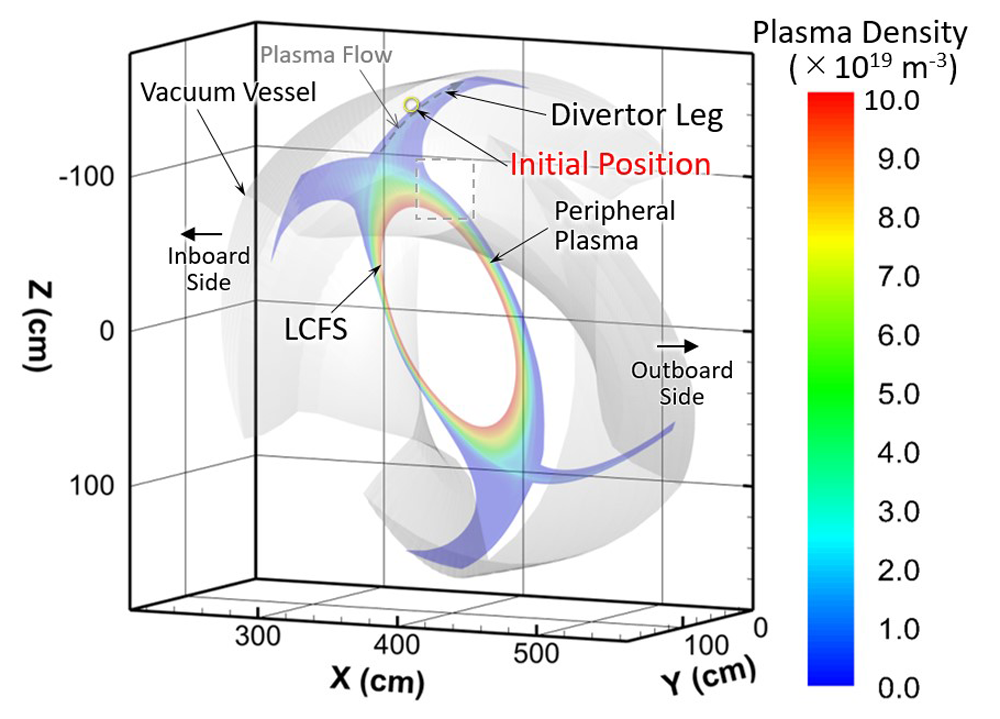

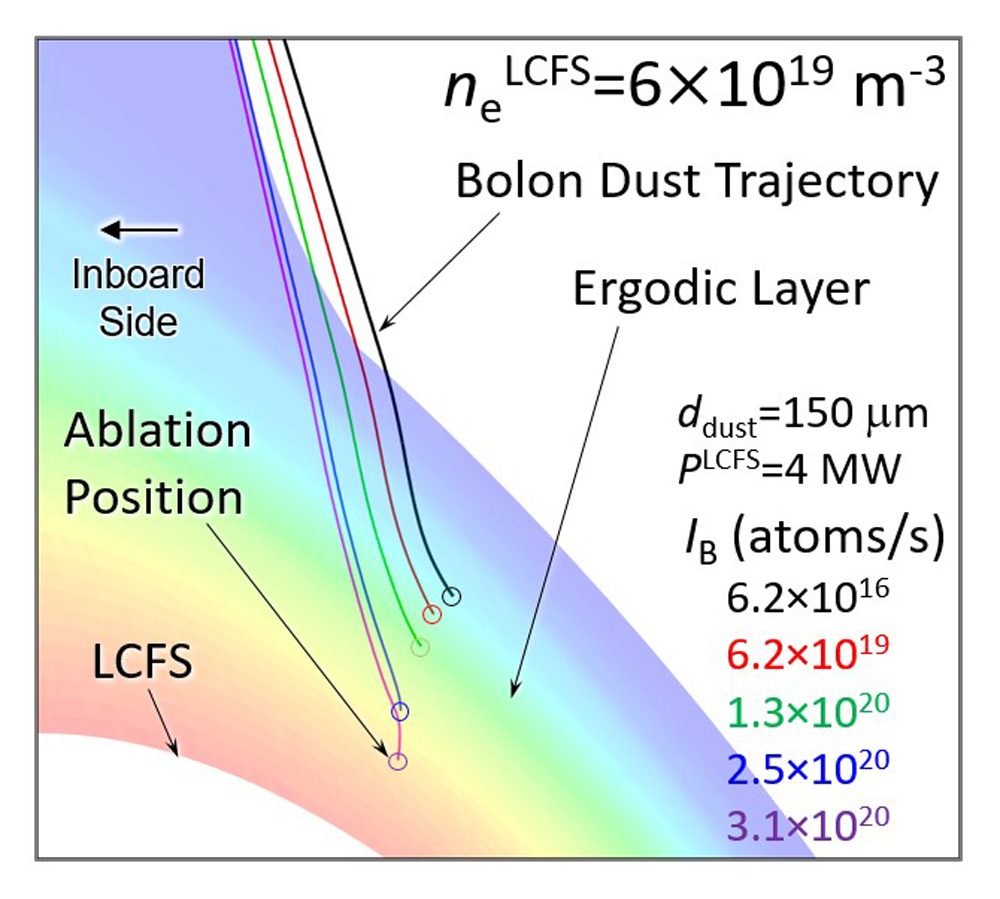

Figure 2 shows the calculations of the trajectories and the evaporation (ablation) positions of the dust particles with the change in the dust drop rate. The trajectories and the ablation positions move to the left side (inboard side of the torus) with the increase in the dust drop rate. These calculations are opposite to what was expected. The reason for this is explained as follows: 1) The dust particles in the plasma produce boron ions, leading to a decrease in the temperature of the peripheral plasma due to radiation by the impurity ions. 2) The lowered plasma temperature induces a decrease in the plasma temperature in the diverter leg. 3) Since the plasma flow velocity is proportional to the square root of the plasma temperature, the drop in the plasma temperature leads to a decrease in the plasma flow velocity in the divertor leg. 4) The lowered plasma flow velocity reduces the deflection of the dropped dust particle trajectories in the diverter leg toward the outboard side, which leads to the movement of the ablation positions toward the inboard side of the torus. This process becomes significant as the increase in the dust drop rate, as shown in Figure 3. The simulations also reveal that even in the highest dust drop rate, the effect of the boron ion flow on the dust particle trajectories is quite small compared to that of the plasma flow.

Consequently, a self-consistent calculation by coupling the edge plasma simulation code and the dust transport simulation code leads to an interesting result which is different from what was expected. It is expected that the simulations will be experimentally verified in plasma discharges. We would like to confirm whether the analytical results can be experimentally reproduced or not.

This research was conducted in collaboration with Mamoru Shoji, Gakushi Kawamura, and Suguru Masuzaki of the National Institute for Fusion Science, Roman Smirnov of the University of California, and Yasunori Tanaka of the Kanazawa University, Federico Nespoli, Erik Gilson, and Robert Lunsford of the Princeton Plasma Physics Laboratory.

The results of this research were published on 29 February 2024 in Contributions to Plasma Physics, an international online journal on plasma physics.