Construction of the measuring system for plasma heat flux to the wall

Significant heat flux is expected at the wall called “the divertor plate” in the fusion device. The present study constructed the system for measuring the divertor heat flux by 2 dimensional (2D) thermography and thermal conduction analysis in LHD. The development of the system accelerates the detailed understanding of the divertor heat flux in the LHD and development of a numerical simulation code with high accuracy.

Significant heat flux is expected at the wall called “the divertor plate” in the fusion device. The present study constructed the system for measuring the divertor heat flux by 2 dimensional (2D) thermography and thermal conduction analysis in the Large Helical Device (LHD). The development of the system accelerates the detailed understanding of the divertor heat flux in the LHD and development of a numerical simulation code with high accuracy.

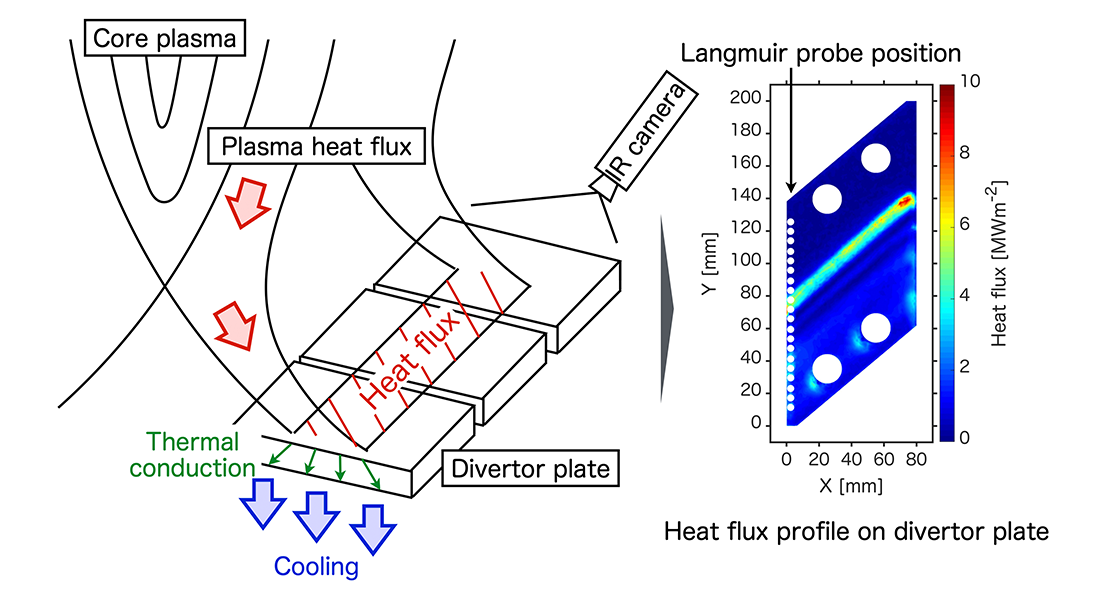

For the efficient pumping of helium ash generated by a fusion reaction, plasma which diffuses from the core plasma region is concentrated at a part of the wall in the fusion reactor. On the other hand, a significant heat flux on the wall is serious problem. Here, the wall exposed to the plasma heat flux is called the divertor plate. Prediction and control of the divertor heat flux is necessary for the engineering design of future fusion reactors.

The LHD is a device equipped with the largest helical divertor configuration in the world. In the previous studies of the LHD, the divertor heat flux was measured by a Langmuir probe, which estimated the heat flux by measuring electron temperature and density in the plasma. The Langmuir probe is a well-known and relatively simple diagnostic while the spatial resolution is low and the measurement region is limited on the divertor plate. The heat flux on the divertor plate includes plasma heat flux, radiation from the plasma and kinetic energy of neutral particles. Second and third components cannot be measured by the Langmuir probe.

The present study developed the IR thermography system which measures the 2D surface temperature on the divertor plate with a high spatial resolution of 1mm. The heat flux profile is reconstructed from the measured temperature profile by using finite element analysis. The analysis solves the transient thermal conduction equation. The system constructed by the present study makes it possible to estimate the effective divertor heat flux, including the contributions of radiation and neutral particles by using the surface temperature of the divertor plate.

The system developed by the present study allows us to analyze the divertor heat flux in detail. We can extrapolate the divertor heat flux in future fusion devices by systematically investigating the divertor heat flux which changes by control parameters, for example, plasma heating power and the amount of gas fueling.

In the present study, the estimation of the heat flux was conducted at one divertor plate. Hopefully, the estimation of the heat flux to all (1,700) divertor plates in the LHD is desired, while it requires many IR cameras and observation ports. Therefore, a next step is prediction of the total divertor heat flux by numerical simulation. The numerical simulation can be compared with experiments in detail by the present system. Future plans are to improve the numerical simulation code by elucidating the physical processes which have not been included in the code. A final goal is to discuss the energy balance in the LHD.

The present study was conducted by the research group led by Yuki Hayashi at NIFS.

The research result was published on 22 January 2021 in Fusion Engineering and Design, an international journal for fusion energy and technology.